- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Why Industrial Facilities Are Switching to Waterproof Motion Sensor Solutions

2025-08-06

Industrial lighting is changing as new trends appear. Many facility managers now pick waterproof motion sensor lighting. This helps them solve problems in tough places. Modern smart lighting systems are strong and work well. They save energy by turning on lights only when needed. These advanced lights make workers safer and help them do more work. Using smart, sensor-based designs gives steady results. It also helps facilities work better in hard industrial areas.

Key Takeaways

Waterproof motion sensor lights help save energy. They turn on only when needed. This can cut power use by up to 75%. These lights are made strong to resist dust, water, and hits. This helps them last longer in tough factory places. Smart controls let managers change brightness and timing from far away. This makes things safer and more comfortable for workers. Using these lights lowers maintenance costs and downtime. This helps factories save money and work better. New sensor and LED technologies make lighting smarter and greener. They also make it more flexible for future needs.

Key Trends in Industrial Lighting

Industry Movement

Lighting in factories is changing fast. Companies want lights that do more than just shine. LED technology is now very popular. It uses much less energy than old lights. This helps companies save money and protect the environment. Many factories use LED lights because they last a long time. These lights also work well in rough places. Using LED lights helps companies be more eco-friendly, which is important to them.

Leaders in the industry pick lights that keep workers safe. They want lights that save energy and last a long time. They pick products that follow strict rules and work in hard places.

Smart lighting is now common in factories. These lights use sensors to change how bright they are. The lights turn up or down based on what is happening. This saves energy and makes work areas safer. Smart controls and IoT are making lighting even better.

Drivers of Change

Many things make companies choose new lighting. Saving energy is a big reason. Motion sensor lighting, especially waterproof types, uses less power. The lights only turn on when someone is there. This is good for big places like warehouses. In these places, lights can stay on for a long time.

- Companies want lights that help them be more green.

- Rules and rewards from the government push companies to use better lights.

- More businesses want smart lights they can change to fit their needs.

- Ceiling lights that cover big areas help keep workers safe and working well.

Waterproof Motion Sensor Lighting

Durability

Factories need lights that can handle dust, water, and bumps. Waterproof motion sensor lighting is strong and built to last. These lights have special protection ratings. For example, the Fanxstar Trilamp A9S has an IP66 rating. This means it keeps out all dust and stops strong water jets. So, these lights work well even if they get wet or dirty.

The IK10 rating makes these lights even tougher. It means they can take hard hits without breaking. This is good for places where machines might bump into them. The table below shows why these ratings matter:

| Rating | Protection Provided | Importance in Industrial Environments |

| IP66 | Dust tight; protected against powerful water jets | Keeps out dust and water, which is important in factories |

| IK10 | High impact resistance | Stops damage from hard hits or people trying to break them |

These lights also have sealed covers and parts that do not rust. This keeps the inside safe from things like water and dirt. It helps the lights last longer. They can work in very hot or cold places because of good heat control. This means they work all year. Factories that use these lights do not have to fix them as often

Energy Efficiency

Saving energy is very important for factories. Waterproof motion sensor lighting turns on only when someone is there. This saves a lot of power. Old lights stay on all the time and waste energy. Smart lights use sensors to turn on only when needed. This can cut energy use by 30% to 50%. This is helpful in big places like warehouses.

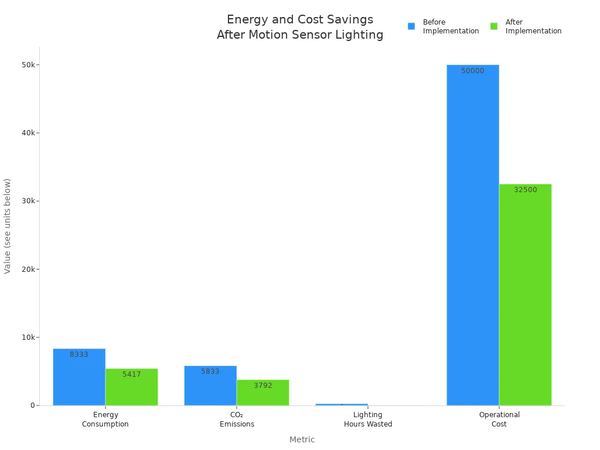

For example, a regular 100-watt light on for 12 hours each night uses about 36.5 kWh each month. But an LED motion sensor light may use just 1.5 kWh each month, depending on how much it is used. The chart below shows how much energy and money can be saved with these lights:

Smart lights can also change how bright they are. They do this based on how many people are there, the time, and how much sunlight comes in. This saves even more energy. Some places save 50–75% on energy after using these lights. Workers can see better and companies spend less money. Using LED lights with motion sensors helps save energy and money for a long time.

Safety

Safety is very important in factories. Waterproof motion sensor lighting helps keep people safe. These lights give good light in busy or dangerous places. High IP ratings keep water and rust away, so the lights keep working in wet or harsh spots. The IK10 rating means the lights do not break if hit by machines or people.

The table below shows how these lights make factories safer:

| Safety Challenge / Environment | Lighting System Feature | Safety Benefit |

|---|---|---|

| Exposure to water, corrosion, and harsh weather | High IP ratings for water and corrosion resistance | Lights last longer and help stop accidents |

| Mechanical impacts and collisions | High IK ratings for mechanical shock resistance | Lights keep working even if hit by something |

| High-traffic or hazardous areas | Robust LED lighting with motion sensors | Makes it easier to see and helps stop crashes |

| Remote or hard-to-access locations | Durable, energy-efficient lighting with smart controls | Lights turn on fast for workers, making repairs safer |

Smart lights can be set to only turn on when needed. They do not turn on for small animals or wind. This saves energy and keeps workers safe. People can see better, there are fewer accidents, and everyone is safer at work.

How Smart Lighting Systems Work

Sensor Technology

Smart lighting systems use sensors to watch what happens in factories. These sensors can sense movement, people, and how bright it is. When someone moves, the sensor tells the lights to turn on. If no one is there, the lights turn off. This helps save energy and gives the right light for people.

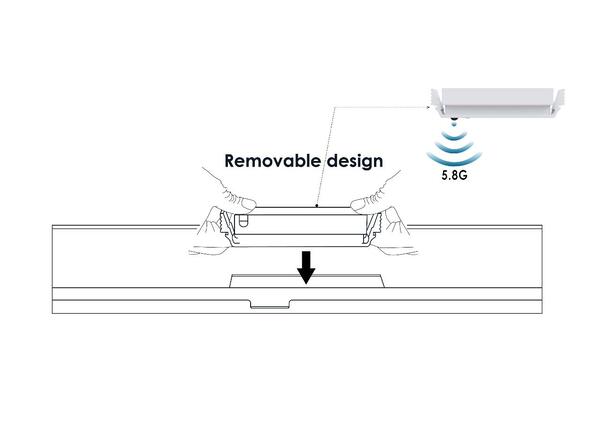

The Fanxstar Trilamp A9S has a 5.8G microwave sensor. This sensor works well even in busy places. It can sense movement through things like walls. The antenna is small, so every spot gets covered with light. The table below shows what makes 5.8G microwave sensors special:

| Feature | Description |

|---|---|

| Frequency | 5.8GHz microwave for reliable detection |

| Anti-interference | Works well in complex industrial environments |

| Penetration Ability | Detects movement through obstacles |

| Intelligent Controls | Adjustable range, hold time, daylight threshold, tri-level dimming |

| Durability | Waterproof and robust for harsh conditions |

| Application | Used in waterproof motion sensor lighting for accuracy and reliability |

These sensors help give the right light at the right time. Workers can see better and feel safer.

Intelligent Controls

Intelligent controls are the main part of smart lighting. They use sensors and timers to turn lights on or off. If a room is empty, the lights go off. If there is enough sunlight, the lights get dimmer. This saves power and helps control the lights better.

Smart lights like the Trilamp A9S can be changed with a remote. You can pick how bright the lights are and what color they show. You can also make different areas have different lights. This makes workers more comfortable and helps them see well. With a remote, you can change the lights fast.

Smart lighting can also work with IoT and AI. This lets people check lights from far away and fix problems before they get big. It helps save money and energy. Smart lighting makes factories safer and helps people work better. It also helps the planet and keeps workers healthy.

Benefits Over Traditional Lighting

Maintenance Reduction

Factories often spend a lot on fixing lights. Old lights break when they get wet or dirty. They can also break if something hits them. Waterproof motion sensor lighting helps stop these problems. These lights have special covers and coatings. The covers keep out water and dust. The inside parts stay safe from harm. Workers do not need to fix the lights as much. Fewer repairs mean less stopping work.

Many new lights, like the Fanxstar Trilamp A9S, use strong materials and tight seals. These things help the lights last longer in tough places. The lights can take hits from machines or people. Factories can focus on making things instead of fixing lights. This way, buildings work better over time.

Tip: Pick lights with high IP and IK ratings. This can help save money and make lights work better in hard places.

Operational Flexibility

Factories need lights that can change for different jobs. Waterproof motion sensor lighting gives this choice. These lights work in many places, like cold rooms or outside. They keep working in rain, snow, or dust. High IP ratings, like IP66, mean the lights work even in storms.

- Waterproof covers and special coatings keep out water and dust.

- Strong seals stop the lights from breaking and needing repairs.

- Parts that handle heat and cold let the lights work in any weather.

- Smart sensors do not turn on for wind or small animals. They only turn on for real movement.

- Some sensors use both infrared and microwave. They work well in fog or snow.

- These lights can connect to smart building systems for remote control.

Managers can change when the lights turn on or how bright they are. They can do this from one place. This helps match the lights to different jobs or times. Controlling lights from far away saves time and keeps workers safe. Workers always have enough light, no matter the weather or time.

Cost Savings

Using waterproof motion sensor lighting saves a lot of money. Old lights stay on all day and waste power. Motion sensors turn lights on only when needed. This lowers electric bills and makes lights last longer. LED lights use less power than old bulbs, so companies save even more.

Factories also save money on fixing and replacing lights. Strong lights break less and last longer. There is less need for extra parts or quick repairs. Over time, these savings grow. Companies can spend more on other things they need.

A simple table shows the difference:

| Feature | Traditional Lighting | Waterproof Motion Sensor Lighting |

|---|---|---|

| Energy Use | High | Low |

| Maintenance Frequency | Frequent | Rare |

| Fixture Lifespan | Short | Long |

| Operational Flexibility | Limited | High |

| Total Cost Over 5 Years | High | Low |

Smart lighting helps companies save money and keep workers safe. This makes the workplace better and helps everyone do more.

Sustainability and Environmental Impact

Energy Savings

Waterproof motion sensor lighting helps factories save energy. These lights use smart sensors to see movement and light. They turn on only when someone is there. This stops energy from being wasted and lowers pollution. Many factories now use solar-powered lights to save more energy. Solar panels take in sunlight during the day. At night, they use this power to run the lights. This means factories use less electricity from the city.

- Motion sensors and photoelectric sensors work together to change the lights right away.

- Solar-powered lights use clean energy from the sun, which is better for nature.

- Remote monitoring lets managers control the lights from anywhere, saving even more energy.

- Better lighting makes work safer and helps with green goals.

Eco-Friendly Materials

Factories want lights that are safe for the earth. Many new lights use materials that are easy to recycle and not harmful. Polycarbonate and other plastics in these lights are strong and last a long time. This means lights do not need to be replaced as often, so there is less waste. Some companies use solar-powered lights with green parts to help the earth even more.

- Strong materials make lights last longer, so less trash goes to landfills.

- Recyclable parts help people reuse old lights.

- Solar lights lower the need for oil and gas, which helps nature.

Case Studies and Real-World Examples

Industrial Success Stories

Many factories have changed a lot after using waterproof motion sensor lighting. Warehouse managers say work areas are brighter and energy bills are lower. In a big distribution center, workers saw fewer dark spots and safer walkways. The lights only turned on when people walked by. This saved power and made the area safer for everyone.

Factory owners also talk about good results. One car plant put waterproof motion sensor lights in its assembly area. The lights stayed off if no one was there. When workers came in, the lights turned on fast. This change cut energy use by almost half. Maintenance teams fixed fewer broken lights. The new lights worked well in dusty and wet places.

“Our team feels safer and we spend less on repairs. The new lights make a real difference,” said a facility manager at a busy logistics hub.

Product Spotlight

The Fanxstar Trilamp A9S is popular in many places. Facility managers in warehouses, factories, and parking garages like this light for its strength and smart features. The Trilamp A9S uses a 5.8G microwave sensor to sense movement up to 6 meters away. It works well in high ceilings and big open spaces.

A new installation in a parking garage showed great results:

| Metric | Before Upgrade | After Trilamp A9S |

|---|---|---|

| Energy Consumption | High | 45% Lower |

| Maintenance Calls | Frequent | Rare |

| Reported Safety Incidents | 3 per year | 0 per year |

The Trilamp A9S helped the garage save money and improve safety. Workers and visitors now have better light and fewer outages. Facility teams spend less time fixing lights and more time on other jobs. The Trilamp A9S shows that smart, strong lighting can change industrial spaces

Future Trends in Industrial Lighting

.

.

Technology Advancements

Industrial lighting is changing with new ideas. Many factories use smart systems that connect to apps and hubs. Managers can control the lights from anywhere. Dual-technology sensors mix PIR and microwave features. This helps stop false alarms and finds movement better.

- Smart technology lets people use remote controls and set schedules.

- Real-time alerts tell managers what is happening right away.

- New LED lights are brighter and use less energy.

- AI features like facial recognition and activity tracking add more security.

- Solar-powered lights help factories use less city electricity.

- Sensors are now more sensitive and can cover bigger areas.

- Daylight sensors can be set to keep lights off during the day.

- This saves energy and stops waste.

- Lights can work with other machines to make work faster.

- Analytics and reports help managers see patterns and keep workers safe.

Market Outlook

The market for waterproof motion sensor lighting is growing fast. Experts think outdoor motion sensor lights will grow by 9.3% each year from 2024 to 2031. This includes lights used in factories. The table below shows how the market could change:

| Market Segment | Forecast Period | CAGR | Market Size Start | Market Size End | Notes |

|---|---|---|---|---|---|

| Outdoor Motion Sensor Lights | 2024 - 2031 | 9.3% | USD 398.64 million (2023) | USD 811.97 million (2031) | Includes Industrial applications segment |

Factories want lights that last longer and save energy. They also want smart features. More companies care about the environment. Solar and eco-friendly materials are getting more popular. New sensor technology and better LEDs will keep changing lighting. The need for smart, strong, and efficient lights will keep going up. Industries want better ways to light their spaces.

Industrial facilities pick waterproof motion sensor lighting for many reasons. These lights help keep workers safe and save money. Smart lighting systems help managers use less energy. They also help stop work from being delayed. Workers can get more done with better lighting. Using these lights is good for the environment. It also helps factories follow important rules. Managers should think about what their facility needs. They should look at the features of each light. Advanced smart sensors, like in the Fanxstar Trilamp A9S, are a good choice. Upgrading to new lighting helps factories grow and handle new changes.

FAQ

What does the IP66 rating mean for industrial lighting?

The IP66 rating means a light keeps out dust and water. It can handle strong water sprays and dirt. This makes it good for tough factory places. Workers know these lights will work in wet or dusty spots.

How do motion sensors help save energy in factories?

Motion sensors notice when people move and turn lights on. Lights only come on when someone is there. This stops wasting power. Factories pay less for energy and lights last longer.

Can waterproof motion sensor lights handle extreme temperatures?

Yes. Many waterproof motion sensor lights work in very hot or cold places. The Fanxstar Trilamp A9S can work up to 50°C. These lights are good for all kinds of factory weather.

Why do facility managers prefer smart lighting systems?

Smart lighting systems let people control lights from far away. They can change how bright the lights are and set timers. Managers get more choices and keep workers safe. They also do not need to fix lights as much.