- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to Choose the Best Teardrop Light for Your Cleanroom?

2025-08-12

To pick the right cleanroom lighting, think about airflow, rules, and how well the light works. A cleanroom teardrop light should let air move easily. It should fit your cleanroom’s class. It must also follow strict hygiene rules. Experts say you should look for features that keep things clean, like sealed and simple-to-clean designs. When you pick a cleanroom teardrop light, remember these important things:

-

Airflow compatibility

-

Lumens and color temperature

-

Energy efficiency

Key Takeaways

-

Pick teardrop lights that let air move easily. Make sure they fit well between HEPA filters. This helps keep your cleanroom safe and clean.

-

Choose lights that match your cleanroom’s class. They should also follow rules like ISO 14644 and FDA cGMP. These rules help with hygiene and safety.

-

Use LED teardrop lights to save energy. They need less fixing and give bright light for a long time.

-

Pick lights that are simple to put in and clean. This helps stop germs and lowers repair costs.

-

Always use a checklist and ask experts for help. This makes sure your lights work well for your cleanroom and keep it running well.

Cleanroom Lighting Basics

Cleanroom Classifications

You will find that cleanrooms have different classes. These classes range from ISO Class 1 to ISO Class 9. Each class controls the number of particles allowed in the air. Here is how these classes affect your lighting needs:

-

ISO Class 1–3: You need lighting that gives off very little heat and almost no particles. These areas are for sensitive work, like making computer chips.

-

ISO Class 4–6: You should use high-performance lighting that is easy to clean and can handle strong cleaning chemicals. These classes are common in pharmaceutical and medical device manufacturing.

-

ISO Class 7–9: These rooms have fewer rules about particles. You still need lighting that helps you see well and keeps contamination low.

The class of your cleanroom will guide you in choosing the right types of cleanroom lighting. You must think about contamination control, heat, and how easy it is to clean the fixtures.

Tip: Sealed fixtures with smooth surfaces help prevent dust buildup and make cleaning easier.

Lighting Standards

When you select cleanroom lighting, you must follow strict standards. These rules keep your cleanroom safe and clean. The main standards include:

-

ISO 14644: This standard sets the rules for cleanroom classes and lighting fixture design. Fixtures must be sealed and easy to clean.

-

FDA cGMP (Title 21 CFR Part 211.44): This rule says you need enough light for safety and quality. Lighting must not cause contamination.

-

EU GMP: This standard focuses on smooth, easy-to-clean fixtures that resist harsh chemicals.

-

EN 12464-1: This guideline gives advice on light levels and color for workplaces, including cleanrooms.

-

NSF P442: This standard covers how to build and test lighting fixtures for pharmaceutical cleanrooms.

-

IEC IP Ratings: These ratings show how well fixtures keep out dust and water.

You will also see that some types of cleanroom lighting use amber or orange colors. These special lights protect materials that react to regular light.

Note: Always check that your lighting has a high IP rating and uses materials that do not shed particles.

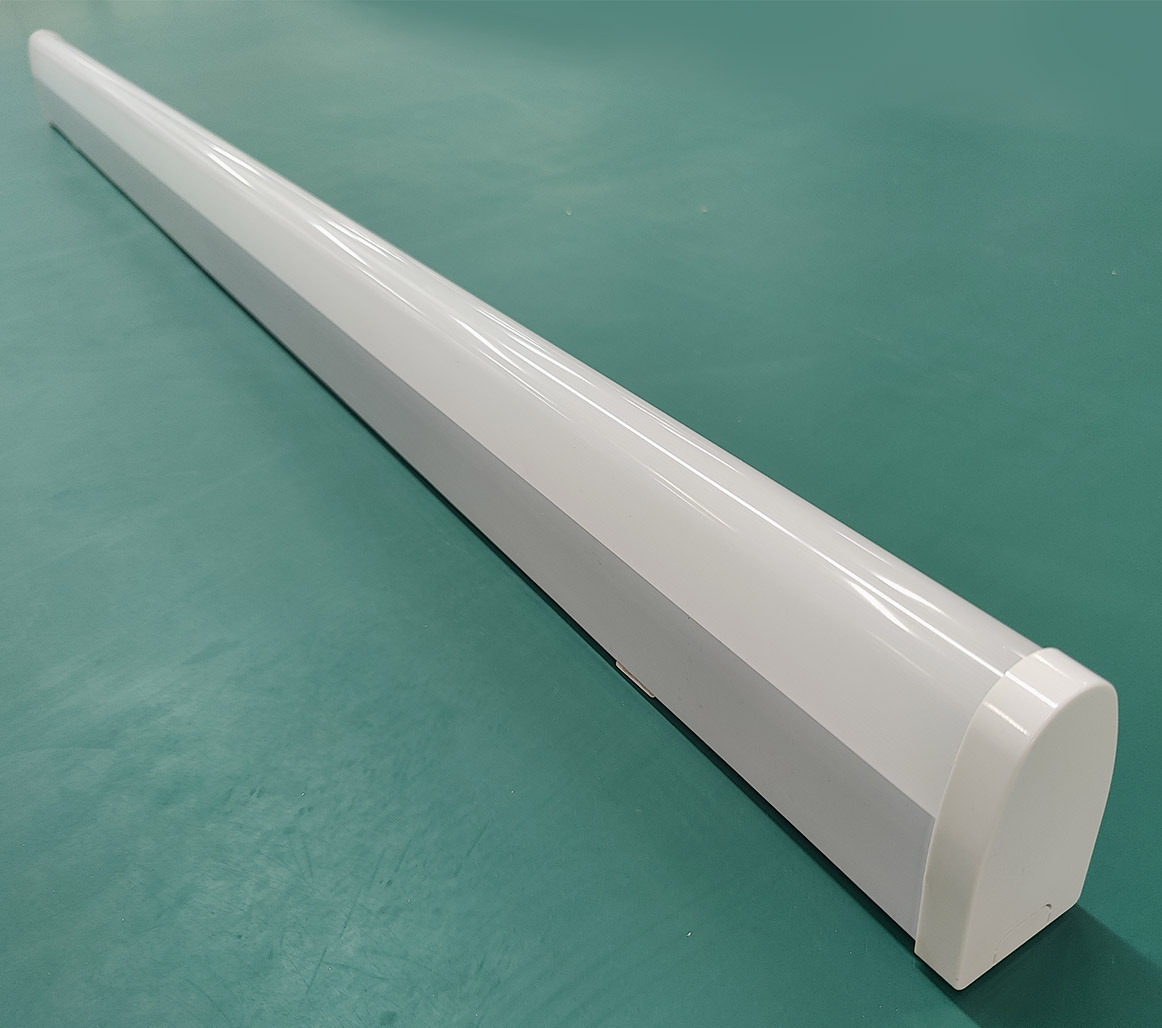

Cleanroom Teardrop Light Features

Airflow and HEPA Compatibility

When you choose a cleanroom teardrop light, you must think about airflow and how it works with HEPA filters. In ISO Class 5 cleanrooms, you often see 100% HEPA ceiling coverage. This leaves little space for regular lights. Teardrop lighting fits between HEPA filters on the T-grid. This setup keeps the airflow smooth and helps your cleanroom meet strict standards. The lights hang below the ceiling by a few inches, so you may need lower-profile models if you want to save headroom. You must make sure the fixtures seal tightly. Even a small gap can let particles enter and cause contamination. In these spaces, you sometimes see recessed lighting used with HEPA filters to keep airflow patterns steady. If you work in a less strict environment, like an ISO Class 7 cleanroom, you still need to think about airflow, but the requirements are not as tight.

Tip: Always check that your teardrop lighting does not block or disturb the airflow from your HEPA filters.

Shape and Installation

The shape of a cleanroom teardrop light matters for both airflow and cleaning. The teardrop design lets air move smoothly around the fixture. This shape helps prevent dust from collecting on the light. You can install these lights on the T-grid between filters or as recessed fixtures. Some models extend below the ceiling, while others sit flush to save space. You should pick a shape and installation method that fits your cleanroom’s ceiling and airflow needs.

-

Choose a shape that matches your ceiling grid.

-

Look for easy-to-clean surfaces.

-

Make sure the installation does not block vents or filters.

Material and Construction

You want your cleanroom teardrop light to last and stay clean. Most teardrop lights use cold-rolled steel or aluminum for the housing. These materials get a baked polyurethane powder coating. This finish creates a hard shell that does not give off gases and stands up to frequent cleaning. You may also see anodized aluminum, which is light, strong, and resists rust. The smooth finish makes it easy to wipe down and helps keep your cleanroom free from particles.

Here is a quick look at common materials and their benefits:

| Component | Material(s) | Benefits |

|---|---|---|

| Frame Channel | Cold-rolled steel or aluminum | Strong and durable |

| Housing | Stainless steel or formed aluminum | Resists rust and damage |

| Finish | Polyester powder paint | Smooth, easy to clean, keeps airflow steady |

| Diffuser | White acrylic with linear prisms | Good light control, easy to clean |

Note: Using the right materials helps you keep your cleanroom safe and easy to maintain.

LED Cleanroom Lighting Advantages

Energy Efficiency

You want your cleanroom to use energy efficient lighting. LED cleanroom lighting gives you a big advantage over older options. When you switch to LED lights, you can cut your energy use by up to 50% compared to traditional fluorescent fixtures. If you compare LEDs to incandescent lights, you save even more—up to 75%. These savings help you lower your power bills and reduce your cleanroom’s carbon footprint.

-

LED cleanroom lights use up to 50% less energy than fluorescent fixtures.

-

You can save up to 75% energy compared to incandescent lights.

-

LED panel lights in cleanrooms save up to 53% energy over traditional lighting.

You get bright, clear light while using less power. This makes LEDs a smart choice for any cleanroom that runs lights for long hours. You also help the environment by using less electricity.

Tip: Choosing energy efficient lighting can help you meet green building goals and lower your operating costs.

Maintenance and Longevity

You want lighting that lasts a long time and needs little care. LED lights offer a much longer lifespan than older types of bulbs. Many LED fixtures work for 50,000 hours or more. This means you do not have to change bulbs as often. Fewer changes mean less risk of contamination in your cleanroom.

LED cleanroom lighting also helps you save on maintenance costs. You spend less time and money replacing bulbs or fixing fixtures. The sealed design of LED fixtures keeps dust and particles out, so your cleanroom stays cleaner. You can focus on your work instead of worrying about your lights.

Note: Longer-lasting lights mean fewer interruptions and a safer, cleaner workspace.

How to Choose Cleanroom Lighting

Assess Airflow Needs

Start by looking at how air moves in your cleanroom. Airflow is very important because it keeps the space free from dust and other particles. You want to make sure your lighting fixture options do not block or disturb the air. A cleanroom teardrop light works well because its shape lets air flow smoothly around it. This helps keep the cleanroom safe and clean. If you use HEPA filters, check that your lights fit between them and do not block the air. Always pick lights that seal tightly to stop particles from getting inside.

Tip: Ask your cleanroom manager or engineer about the airflow pattern before you choose cleanroom lighting.

Determine Lumens and Color Temperature

Next, think about how bright you need your cleanroom to be. The amount of light is measured in lumens. You need enough light to see your work clearly, but not so much that it causes glare. The right color temperature also matters. In many semiconductor cleanrooms, you will see color temperatures of 4000 K or 5000 K. These levels help you see colors correctly during inspections.

| Feature | Description | Benefit |

|---|---|---|

| Color Temperature | 4000 K and 5000 K | Ensures color accuracy in inspections |

Pick a color temperature that matches your tasks. For most cleanrooms, 4000 K gives a neutral white light. If you need even more color accuracy, 5000 K works well. Always check the lumens and color temperature before you buy.

Check Compliance and Certification

You must make sure your cleanroom lighting meets all rules and standards. Look for certifications like ISO 14644, FDA cGMP, and EU GMP. These show that the lights are safe and easy to clean. Many people run into problems with compliance. Some common issues include long wait times for special lighting parts, which can slow down repairs. If you do not have spare parts like ballasts, drivers, or LED panels, you might face downtime. Regular checks help you find electrical problems early. Using LED lights with long life and low heat helps you avoid frequent changes and keeps your cleanroom under control.

-

Long lead times for special lighting parts can cause delays.

-

Preventative maintenance helps you spot electrical issues early.

-

Keeping spare parts on hand reduces downtime.

-

LED lights with long life and low heat output are best for cleanrooms.

Note: Always ask for proof of compliance and certification when you choose cleanroom lighting.

Evaluate Installation and Maintenance

Think about how easy it is to install and care for your lights. Some lights need special tools or skills to put in place. Others are simple and quick to install. Pick a design that fits your ceiling and does not block vents or filters. Maintenance is also important. LED lights last a long time and need less care. This means you spend less time changing bulbs and cleaning fixtures. Fewer changes mean less risk of bringing dust into the cleanroom.

Callout: Talk to a cleanroom lighting expert if you are not sure which option is best. Experts can help you find the right fit for your space and needs.

Checklist for Choosing Cleanroom Lighting:

-

Check airflow needs and HEPA filter layout.

-

Decide on the right lumens and color temperature.

-

Confirm all compliance and certifications.

-

Choose easy-to-install and low-maintenance fixtures.

-

Keep spare parts ready for quick repairs.

-

Consult with cleanroom lighting experts.

Cleanroom Teardrop Light Checklist

Quick Reference

A checklist can help you pick teardrop lights for your cleanroom. It helps you remember each step and make good choices. Use this quick guide so you do not forget anything important.

A checklist makes sure you cover airflow, cleanliness, and lighting quality. It also helps you think about energy use and following the rules.

Key Points to Review:

-

Find out your cleanroom’s class and how you use it. This tells you what kind of lighting and cleanliness you need.

-

Look at your ceiling type. T-grid ceilings that can change height (8 to 10 feet) make it simple to put in and take care of teardrop lights.

-

Check that your ceiling panels do not have seams. This stops dirt from getting in and keeps your cleanroom safe.

-

Make sure your teardrop lights fit between HEPA filters and do not block air. Some lights can mess up the airflow, so always check where you put them.

-

Pick LED lighting for bright light that lasts a long time. LED lights also help you save energy.

-

Make sure it is easy to take out panels and lights for cleaning or fixing. You should be able to do this without making your cleanroom dirty.

-

Think about your HVAC needs. Ceiling tiles might need air-return grills or extra filters, which can change where you put your lights.

-

Always check for certifications and make sure you follow ISO and GMP standards.

| Checklist Item | Why It Matters |

|---|---|

| Cleanroom class and usage | Tells you what lighting and cleanliness you need |

| Ceiling system and panels | Makes it easy to install and take care of lights |

| Airflow and HEPA compatibility | Keeps air moving right and stops contamination |

| LED lighting integration | Saves energy and lasts a long time |

| Maintenance access | Cuts down on repairs and keeps your cleanroom safe |

| Compliance and certification | Follows safety rules and laws |

Tip: A checklist helps you look at everything, like airflow and energy use, so you can pick teardrop lighting that works best for your cleanroom.

Picking the best teardrop light for your cleanroom takes some thought. You need to check how air moves in the room and how much space is on the ceiling. Make sure the lights follow all the rules for your cleanroom. Choose lights that fit your cleanroom class and let air flow easily. Teardrop lights are great when the whole ceiling has filters. Always use a checklist to help you decide. Ask experts for help with putting in, caring for, and checking the lights. Their help keeps your cleanroom safe and working well.

FAQ

What makes a teardrop light different from a regular cleanroom light?

Teardrop lights have a special shape. You see smooth curves that let air flow around the fixture. This design helps prevent dust buildup and keeps your cleanroom cleaner than standard flat lights.

Can you use LED teardrop lights in all cleanroom classes?

Yes, you can use LED teardrop lights in most cleanroom classes. Always check the product’s certifications. Make sure the light meets your cleanroom’s ISO or GMP requirements before you install it.

How do you clean a teardrop light in a cleanroom?

You should use a lint-free cloth and an approved cleaning solution. Wipe the surface gently. Avoid harsh scrubbing. Always follow your cleanroom’s cleaning protocol for best results.

What certifications should you look for in cleanroom lighting?

Look for ISO 14644, FDA cGMP, and EU GMP certifications. These show the light meets strict cleanroom standards. Some lights also have NSF or IP ratings for extra safety.

Do teardrop lights affect your cleanroom’s airflow?

No, teardrop lights help keep airflow steady. Their shape lets air move smoothly around them. You should always check that the light fits well between HEPA filters and does not block vents.