- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Essential Tips for Maintaining and Cleaning Medical Lighting Equipment

2025-09-02

Medical lighting is very important in surgeries. It helps keep patients safe and comfortable. Surgical lights help make the area clean and help doctors do their best work. If you do not clean and take care of the lights, patients may not get good care. There could be more infections. Hospitals might have to pay fines. If surgical lights do not work well or break, it can stop doctors from helping patients. It can also make the area less safe and clean. Taking care of surgical lights stops big repairs. It helps the lights last longer. It also shows how important surgical lights are in hospitals.

Tip: Clean and check surgical lights often to keep everyone safe and comfortable.

Key Takeaways

- Turn off medical lights before cleaning. Let them cool down first. This keeps you safe and protects the equipment.

- Use safe disinfectants like hydrogen peroxide. Clean with soft, lint-free cloths. This helps clean lights without hurting them.

- Clean handles and controls after every use. This stops germs from spreading to others.

- Check lights often for any damage. Replace bulbs when needed. Look at electrical parts to make sure lights work well.

- Use covers to protect surgical lights. Manage heat the right way. Schedule professional calibration to keep lights safe and working longer.

Medical Lighting Cleaning

Power Off and Cool Down

Always turn off the medical lighting before cleaning. Wait for the lights to cool down first. This keeps you safe from burns and shocks. Safety is very important when cleaning lights. Put a “Do Not Enter” sign near the area. This lets others know cleaning is happening. Wear gloves, gowns, and masks to stay safe and stop infection.

Tip: Do not hurry the cool-down time. Hot lights can hurt you or ruin cleaning tools.

Disinfectant and Cloth Selection

Picking the right disinfectant helps stop germs and keeps things clean. Hydrogen peroxide and peracids are good for cleaning medical lights. They kill germs and do not harm the equipment. UVC light at 222 nm also kills germs well and leaves no chemicals behind. Sodium hypochlorite (bleach) cleans well but can hurt metal and change its color, so do not use it on lights. Quaternary ammonium compounds last a long time, but they do not kill every germ and work less if there is dirt.

Use lint-free wipes made from soft materials to clean light parts. These wipes do not leave fibers and soak up disinfectant well. They help keep medical lights free from lint and residue. In special areas, you may need to wear lint-free suits with hoods and boot covers to lower the risk of germs.

| Disinfectant Type | Effectiveness | Surface Compatibility | Residue/Corrosion Risk |

| Hydrogen Peroxide/Peracids | High | Excellent | None |

| UVC Light (222 nm) | High | Excellent | None |

| Sodium Hypochlorite | High | Poor (metals) | Corrosive/Discolors |

| Quaternary Ammonium | Moderate | Good | None |

Cleaning Handles and Controls

Handles and controls are touched a lot and can spread germs. Clean and disinfect these parts after each use. Use plastic wraps on light handles as a barrier. Take off and change the covers between patients. Clean and disinfect handles and controls before putting on new covers. This helps keep things clean and stops germs.

Here are steps for cleaning and disinfecting light parts:

1.Get all cleaning supplies, like PPE, disinfectants, and lint-free wipes.

2.Take away trash and used items carefully to stop germs from spreading.

3.Wipe off dust and dirt first.

4.Put disinfectant on and let it sit for the right time.

5.Wipe the area with a lint-free cloth.

6.Change cleaning wipes often to stop spreading germs.

7.Check to make sure everything is clean and disinfected.

Cleaning handles and controls often helps stop infection. It keeps medical lights safe for everyone. Follow written rules about how often to clean these parts. How often you clean depends on how much people touch the equipment, the risk of germs, and what patients need.

Note: Cleaning light fixtures and handles after every use is the best way to stop germs from spreading.

Surgical and Procedure Lights Inspection

Physical Damage Check

You should clean and check the lights often. This helps surgical and procedure lights work well. First, look for any damage. Scratched or cloudy lenses make lights less bright and clear. Chemicals can hurt control panels and knobs. Too much cleaning liquid can cause water damage. Heat and moisture can harm fiber-optic parts. Rough handling can cause misalignment or mechanical damage. Cracks or breaks on light heads or arms can happen from bumps. Worn bearings or loose arms make lights hard to move.

- Scratched or cloudy lenses

- Brittle control panels and knobs

- Water damage from cleaning

- Heat and moisture damage to fiber-optics

- Misalignment or mechanical damage

- Cracks or fractures on light heads or arms

- Worn bearings or drifting suspension arms

Lights that do not work are a common problem. Sometimes, the area under the lights gets too hot. This can make people uncomfortable. You need to check the lights often to find problems early.

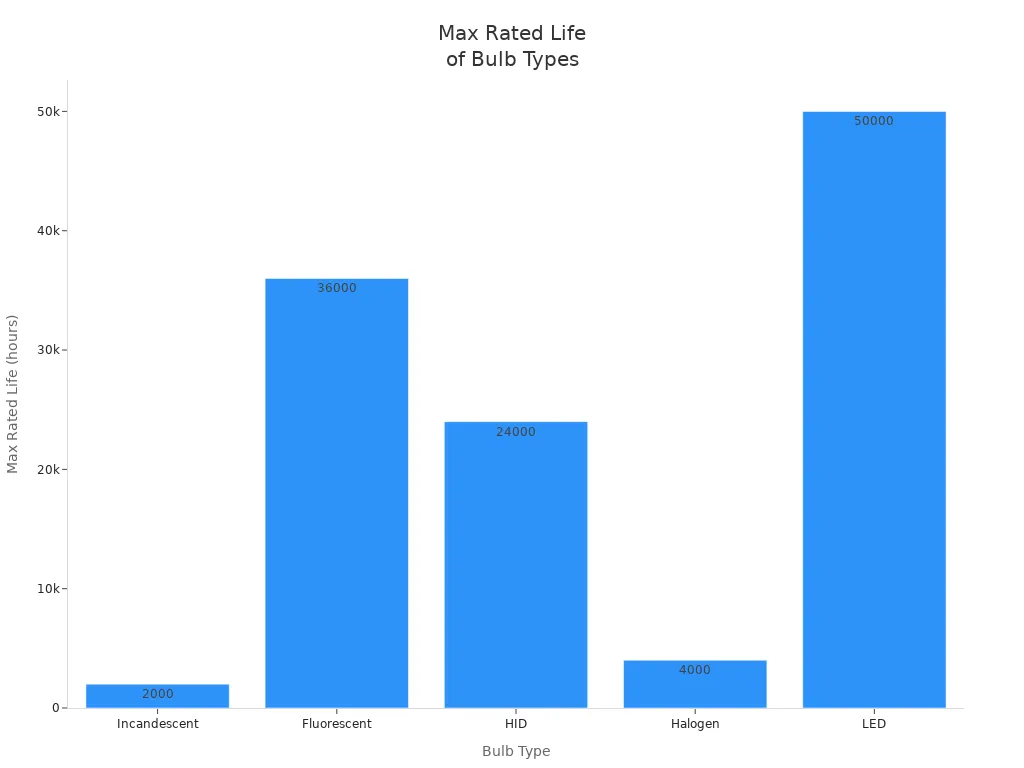

Bulb and LED Replacement

Bulbs and LEDs need regular checks. Change them when the manufacturer says to. This keeps the lights working well. LEDs last longer than other bulbs. You should still check them every year. Here is a table to show how long bulbs last:

| Bulb Type | Average Rated Life (hours) |

| Incandescent | 750 - 2, 000 |

| Fluorescent | 24, 000 - 36, 000 |

| HID | 10, 000 - 24, 000 |

| Halogen | 2, 000 - 4, 000 |

| LED | 40, 000 - 50, 000 |

Always follow the manufacturer's instructions for care. Change bulbs and LEDs before they stop working. This helps avoid problems during surgery.

Electrical Components Review

You need to check electrical parts often. Follow these steps:

1.Check all electrical equipment before each use.

2.Look for signs of damage.

3.Clean and replace broken parts.

4.Make sure lights work and are set right.

5.Write down all checks and repairs.

6.Use safety lists for every check.

7.Tell someone and fix problems fast.

8.Teach staff how to use lights safely.

9.Do not overload circuits and keep lights dry.

Check LED drivers, switches, dimmers, and brackets. Test controls and presets. Look at mounting hardware, safety cables, and bearings. Make sure lights move easily and do not drift. Measure brightness and focus. Follow instructions and keep records. Change parts when needed and check wires and emergency power.

Regular checks help you follow health rules. Surgical lights are important for patient care. You must keep them safe and working well. Good records and regular care keep your lights ready for every procedure.

Best Practices for Maintaining Surgical Lights

Use of Covers

Covers protect surgical lights from dust and germs. They act like a shield and keep lights clean between uses. When you put covers on lights, fewer particles land on them. This helps with sterilization and stops infection. Always take off and change covers after each use. Clean the light before adding a new cover. Covers also keep moisture away from the light. Moisture can hurt sensitive parts. Using covers is a smart way to care for surgical lights. It helps them last longer.

Tip: Pick covers that fit well and let light shine through. Change covers if they get damaged.

Heat Management

It is important to control heat in surgical lights. High heat can break equipment and make people uncomfortable. Choose lights that make less heat, like LED or halogen. These lights are cooler than xenon. Set the lights to the lowest brightness that still works well. For LED lights, use about 40% brightness to keep things safe. Never let the light touch skin or other materials. Turn off lights when you do not need them. Put connectors on trays, not on skin or cloth. Use fiber optic materials like acrylic because they move less heat. Add infrared filters and fans to cool the area. Always follow safety rules and instructions from the maker. These steps help stop overheating and keep surgical lights working well.

| Light Source | Heat Output | Safety Features |

| LED | Low | Infrared filter, fan |

| Halogen | Moderate | Infrared filter, fan |

| Xenon | High | Needs careful intensity control |

Antimicrobial Finishes

Antimicrobial finishes help stop germs on surgical lights. These coatings keep microbes from growing on the surface. Surgical lights have smooth edges and strong protection. This makes cleaning easier and helps with disinfection. The finishes stop dust and dirt from sticking. All surfaces resist rust, so you can use strong cleaning methods like chemicals, gas, or UV. Antimicrobial coatings work all the time to lower bacteria. They help keep the operating room clean and safe. Using lights with antimicrobial finishes is a smart way to care for surgical lights. It helps with cleaning and sterilization.

Note: Antimicrobial finishes help cleaning and disinfection work better. They make infection control stronger.

Medical Lighting Maintenance Scheduling

Professional Calibration

You should plan for professional calibration of medical lighting. Calibration makes sure the lights are bright enough and the color is right. It also checks that the focus is correct for medical work. Trained technicians use special tools to test and fix each light. You need to add calibration to your normal maintenance plan. This helps stop sudden problems and keeps lights working well. When you follow a schedule, your equipment lasts longer and breaks down less. Hospitals with CMMS can keep track of calibration dates and results. This helps them follow rules and work better.

Tip: Have certified professionals calibrate your lights at least once a year. This keeps them accurate and working well.

Compliance Checks

You have to follow strict rules for medical lighting care. These rules keep patients and staff safe. Some important rules are checking emergency lights and life safety systems often. Staff must be trained and all work must be written down. New lights and upgrades should use LED technology. Restrooms need occupancy sensors and there are limits on how much power lights can use. The Life Safety Code says emergency lights must work if the power goes out. You should keep records of all checks and tests. Inspectors want to see proof that you check and fix lights often and that teams work together.

- Check emergency lights every month.

- Teach staff to spot problems with equipment.

- Use CMMS to track problems and rule-following.

- Write down all work and tests.

- Plan yearly tests to make sure everything works.

| Test Frequency | Duration | Description |

| Monthly | 30 seconds | Test emergency lights for short power loss. |

| Annually | 90 minutes | Pretend there is a long power outage to check if lights last. |

Note: Keeping good records and fixing things early helps you pass inspections and avoid big fines.

Emergency Repairs

You need to be ready for emergency repairs to keep patients safe. Hospitals must always watch their electrical systems. Do not use extension cords in patient care areas because it is unsafe. Put UPS systems in important places. Give backup power and automatic switches to keep lights on. Follow all electrical safety rules from around the world and your country. Test emergency lights every month and year. Keep all repair and check logs current. Doing regular checks lowers the chance of sudden breakdowns and costly repairs. Preventive care saves money and makes equipment more reliable.

- Watch electrical systems all the time.

- Match preventive care with what makers suggest.

- Test emergency lights every month and year.

- Keep special power systems working in important areas.

- Make sure staff know what to do and are supervised.

Tip: A good maintenance plan keeps patients safe, saves money, and helps you pass inspections.

You help keep surgical lights clean and working well. Cleaning them often and taking care of them stops damage. It also helps the lights last longer. When you do things the right way, you make the area safe and clean. This helps keep patients safe and comfortable. Good surgical lights help doctors see better. They help stop mistakes and make everyone feel better. Check your cleaning rules or plan an inspection to give the best care.

FAQ

How often should you clean and inspect the lights in a surgical room?

Clean and check the lights after every surgery. Doing this often helps stop germs and infection. It keeps patients safe and comfortable. A regular cleaning plan makes sure the lights work well. It also keeps the room clean and safe.

What disinfectants are best for cleaning light components?

Use disinfectants that are safe for medical lights, like hydrogen peroxide or quaternary ammonium. These help kill germs and keep things clean. Always read and follow the maker’s instructions when cleaning lights. This helps make the room sterile.

Why is it important to keep the light away from moisture?

Moisture can hurt surgical lights. Keep lights dry to stop electrical problems and stay safe. This also lowers the chance of infection. Dry lights help doctors care for patients better.

What are the best practices for maintaining surgical lights?

Check the lights often and follow a cleaning plan. Clean and inspect them, use covers, and keep them cool. These steps help the lights work well, keep people comfortable, and stop germs.