- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What Is the Difference Between Cold Storage and Ordinary Lights and How Do We Choose Them?

2025-02-24

Cold storage light refers to a temperature that is usually below 0° C, or even -20°C or lower environments and it needs luminaires with strong low-temperature resistance. While the ordinary one just needs to operate at normal temperature, it is not necessary for the low-temperature resistance of the requirement of luminaries.

On the one hand, the humidity of the cold storage light is higher than the ordinary one, it is easier to produce condensation, and the moisture resistance of the luminaires is also more stringent than normal lighting. On the other hand, cold storage lights are generally set up in dense areas of cargo. We need to consider fire and explosion-proof luminaire safety factors. So the safety requirement is stricter than the normal one.

At the same time, the cold storage lighting needs to provide enough lighting brightness to make sure that the personnel working in the cold storage can see the goods, but also consider energy saving, and reduce operating costs. However, general lighting requirements are relatively simple, they can satisfy our normal daily life demands.

Generally speaking, the low-temperature resistance of ordinary luminaries is relatively poor, and they are easily broken and fail such as lamp breakage, start-up difficulties, etc. Ordinary lamps are poor in moisture resistance and lifespan and safety will be shortened as well they will also have security risks like flammability and residual current.

During the usage of a cold storage environment, there are some special requirements for the design of the cold storage luminaries. Such as the good low-temperature resistance. To ensure that the luminaires can operate normally, special materials and processes are necessary. Good sealing performance to prevent wet gas from entering the interior of the lights is very important as well. at the same time, to ensure the safety of the luminaries, it is best to utilize high-efficiency light sources and optimize design to reduce the energy consumption of lamps.

How many types of cold storage lights?

1.LED cold storage light: energy saving, long life, safe and reliable, is the current mainstream choice.

2.Fluorescent cold storage lights: the price is lower, but the energy consumption is higher, and it is gradually replaced by LED lights.

3.Other cold storage lights: such as gold halide lamps, high-pressure sodium lamps, etc., are less used.

What is the key selection of the cold storage light?

According to the cold storage temperature selection: different temperatures of the cold storage need to choose different low-temperature levels of lamps.

1.Consider moisture resistance and corrosion resistance: the cold storage environment is humid, and the lamps should have good moisture resistance and corrosion resistance.

2.Focus on safety: Choose lamps with fire and explosion-proof certification to ensure the safety of cold storage.

3.Choose energy-efficient lighting: LED lights are preferred to reduce operating costs.

4.Consider installation and maintenance: Choose lamps that are easy to install and maintain to reduce later maintenance costs.

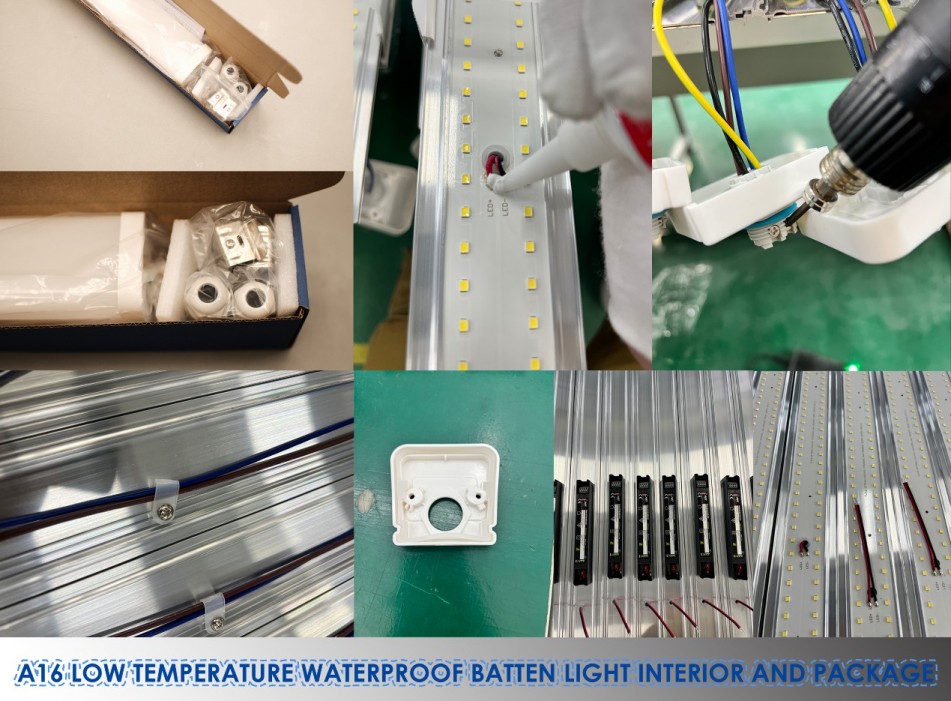

The Trilamp Al6 splicing version is based on the conventional Al6N version to increase the high-voltage splicing function, and improve the light efficiency to 1 40LM/w, which will save 20% more energy than the conventional version.

Taking the biggest seller, A1 6-4FT-Extra, as an example, the A16 splicing version can connect up to 20 strips at 230V, with Max. Wattage per run of connected fixtures is 800w.

This innovative design, with a very small manufacturing cost, reduces the wiring cost of the construction site as much as possible, and improves the installation efficiency.

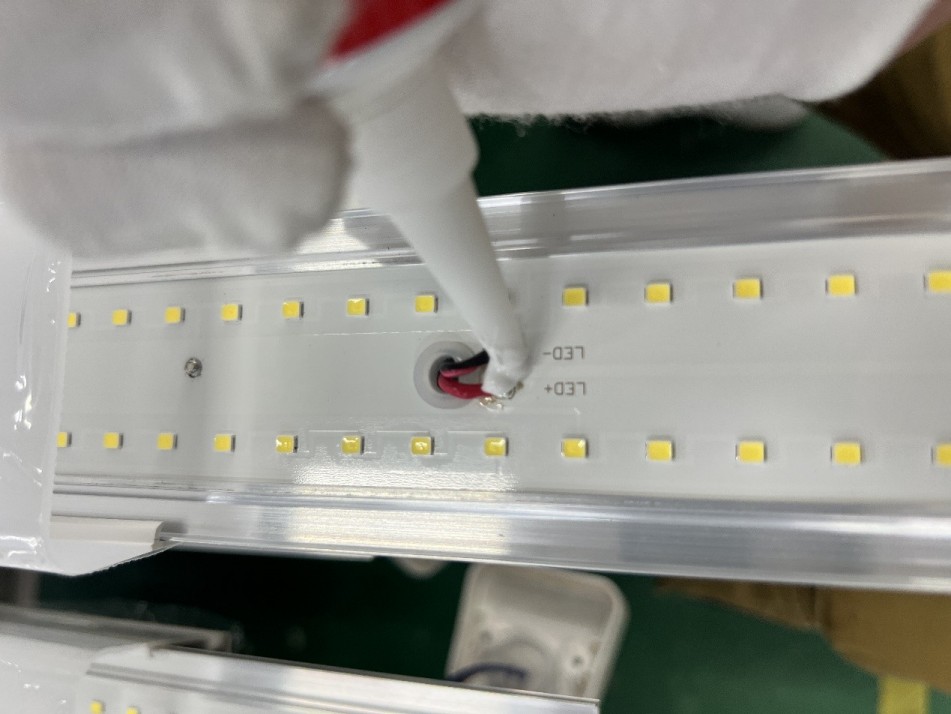

In terms of details, each Al6 has passed a strict lP65 waterproof test before leaving the factory. The rubble plug is placed on the non-use end to meet the customer's different application scenarios of independent and multi-splicing.

Fanxstar Trilamp A16 is specially designed for low-temperatures that can work under a -50℃ environment and let’s see the inside details about it.